144mva 35kv Furnace Transformer for Metallurgical Electric Arc Furnace Transformer

Electric furnace transformers are transformers which supply power to the electric furnaces. It can drop high voltage to the working voltage the electric furnaces need.

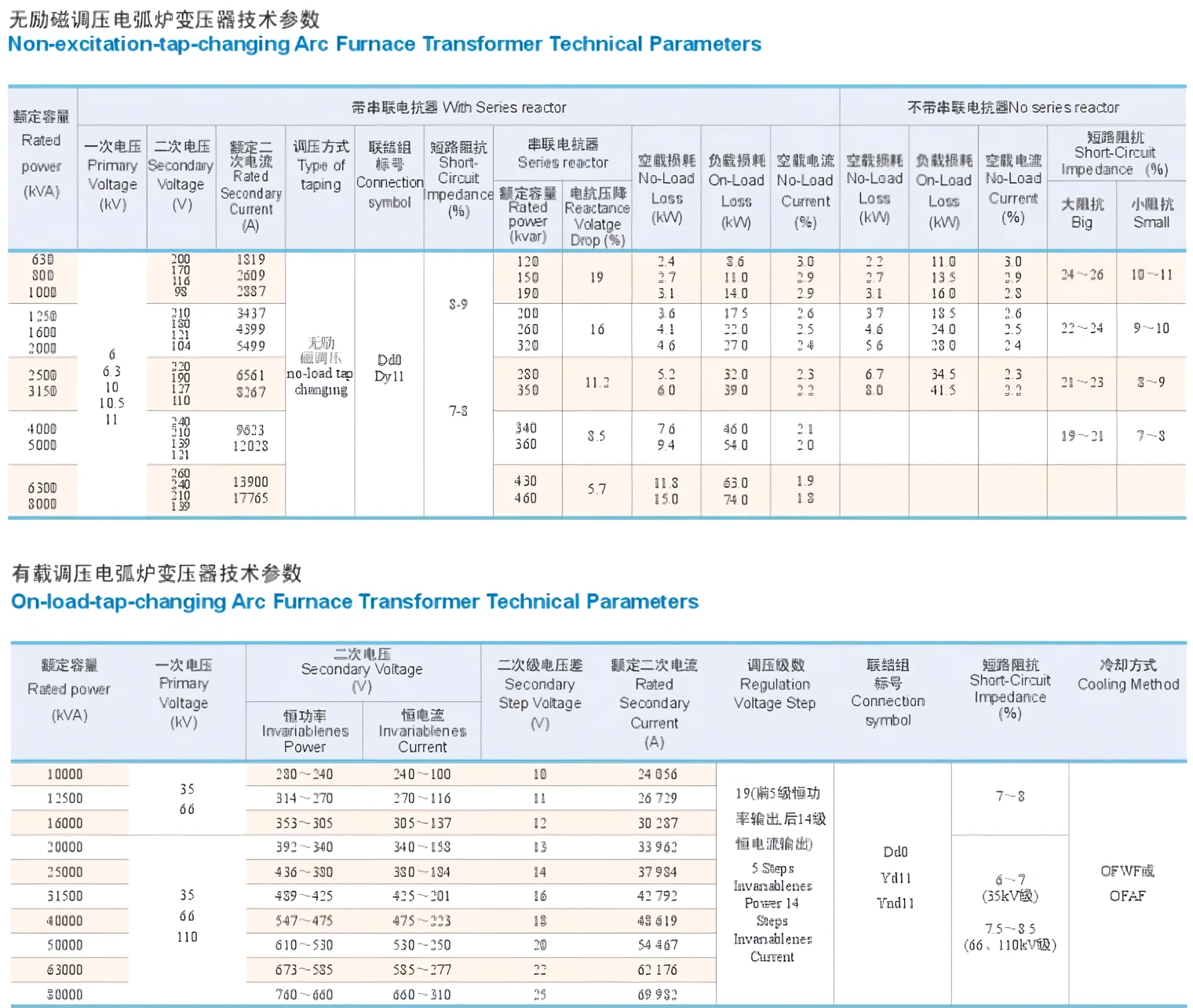

There are many kinds of electric furnaces,so there are many kinds of electric furnace transformers cooperating with them.Now,our company manufactures following electric furnace transformers:electric furnace transformers used in steelelectric furnaces(including on-laod,no-load and enclosed reactor) ; mineral hot furnace transformers used to smelt kinds of iron alloys,hydrosilicons,carbides,etc(single phase,three phases on-load and no-load tap changer). They are low loss and energy-saving products.Cooling methods are self-cooling, forced oil water cooling, etc.It can be designed specially according with customers' requirements. The model of the electric furnace transformer is expressed as follows:

Model NO.: HSSPZ-144000/33

Cooling Method: Oil-immersed Type Transformer

Winding Type: Multi-winding Transformer

BASIC INFO.

| Model NO. | HSSPZ-144000/33 | No Load Losses | 52kw |

| Cooling Method | Oil-immersed Type Transformer | Load Losses at 75 | 280 Kw ( 60mva 950V ) (Including LV Lead Losses |

| Winding Type | Multi-winding Transformer | Cooling System | Ofwf, Double Tube, 2 Coolers in Service. |

| Usage | Electric Arc Furnace Transformer | On-Load Tap Changer | Mr |

| Frequency Characteristics | Power Frequency | Testing | Routine Test According to IEC Standard |

| Shape of Core | Ring | Transport Package | Nuke Packing; Wooden Cases |

| Brand | Ville | Specification | IEC |

| Arc | Furnace Transformer | Trademark | Ville |

| Steel | Furnace | Origin | Ningbo China |

| Type | Calcium Carbide Furnace Transformer | HS Code | 8514901000 |

| Test Certification | Kema | Production Capacity | 10/Years |

| Reference Standard | IEC 60076 |

THE MEANING OF MODEL

H--Steelmaking arc furnace,HJ--ladle furnace,HZ--electro-slag furnace,HC--calcium carbide furnace,HK--mineral

hot furnace,HG--line frequency induction furnace;

Number of phase:D--single phase,S--three phase;

Types of cooling device :ONAN,wind cooling F,water cooling S.

The methods of oil circulation:natural circulation,forced oilcirculation P.

Tap changer:off-circuit tap changer,OLTC Z.

Enclosed attached device:changing leakage flux,enclosed reactor K.

Rated capacity:KVA. max 140MVA

Voltage class:KV. 35KV

TECHNICAL PARAMETERS

|

General data

|

|

|

Operating Voltage |

33KV±3% |

|

Frequency |

50Hz±1% |

|

Rated capacity |

144 MVA |

|

Over load power |

144MVA plus 20%,30 min. |

|

Rated primary current |

1049.7 A |

|

Insulation Level (AC/LI) |

85/200 kV |

|

Vector group |

D/d0 with booster regulation transformer inside. |

|

Secondary connection |

Delta OPEN |

|

System short circuit capacity at 33kV side. |

1100 MVA |

|

Secondary outlet |

Terminals with Bus bars come out from top cover. 8 Buss bars by |

|

Max. Secondary current |

Approximate 42120 A |

|

Secondary voltage range |

950-500 V. |

|

a) Constant power |

950V-822.4 V at 60 MVA |

|

b) Constant current |

About 42062 A within 824V-500V |

|

c) Short-circuit voltage |

8 % (at 950V,60MVA) |

|

Type of tap changer |

On load tap-changer: |

|

a) Manufacturer |

MR, |

|

b) Number of tapes |

17 voltage steps with 18position See attached data sheet of 60 |

|

c) Oil filter equipment for OLTC |

yes |

|

Cooling |

OFWF |