Induction Furnace Rectifier Transformer for Copper Melting 1000kVA 10kv 0.66kv

Rectifier transformers face high operating currents combined with a huge amount of harmonic content due to the distrorted waveform caused by the semiconductor converters connected to the transformer. Typical applications are for : DC arc furnaces,electrolysis,scrap melting furnaces,aluminum smelter,graphitising furnaces.traction substatios, metal refining and inverters for variable speed drives.

Several solutions can be provided according to the rectifier features and the end -user need, Rectifier transformer is often coupled with components as regulating transformers(or autotransformers), saturable reactors and interphase transformers. All these components maybe assembled in one or in separate tanks.

Model NO.: ZS-1000KVA 0.66KV

Cooling Method: Oil-immersed Type Transformer

Winding Type: Two-winding Transformer

BASIC INFO.

| Model NO. | ZS-1000KVA 0.66KV | Specification | IEC, CE |

| Cooling Method | Oil-immersed Type Transformer | Trademark | VILLE |

| Winding Type | Two-winding Transformer | Origin | China |

| Certification | ISO9001-2000, ISO9001 | HS Code | 86 |

| Usage | Rectifier Transformer | Production Capacity | 500sets/Month |

| Frequency Characteristics | Intermediate Frequency | Packaging & Delivery | |

| Shape of Core | Ring | Package size per unit product | 1.00cm * 1.00cm * 1.00cm |

| Brand | Ville | Gross weight per unit product | 1.000kg |

| Transport Package | Wooden Case | ||

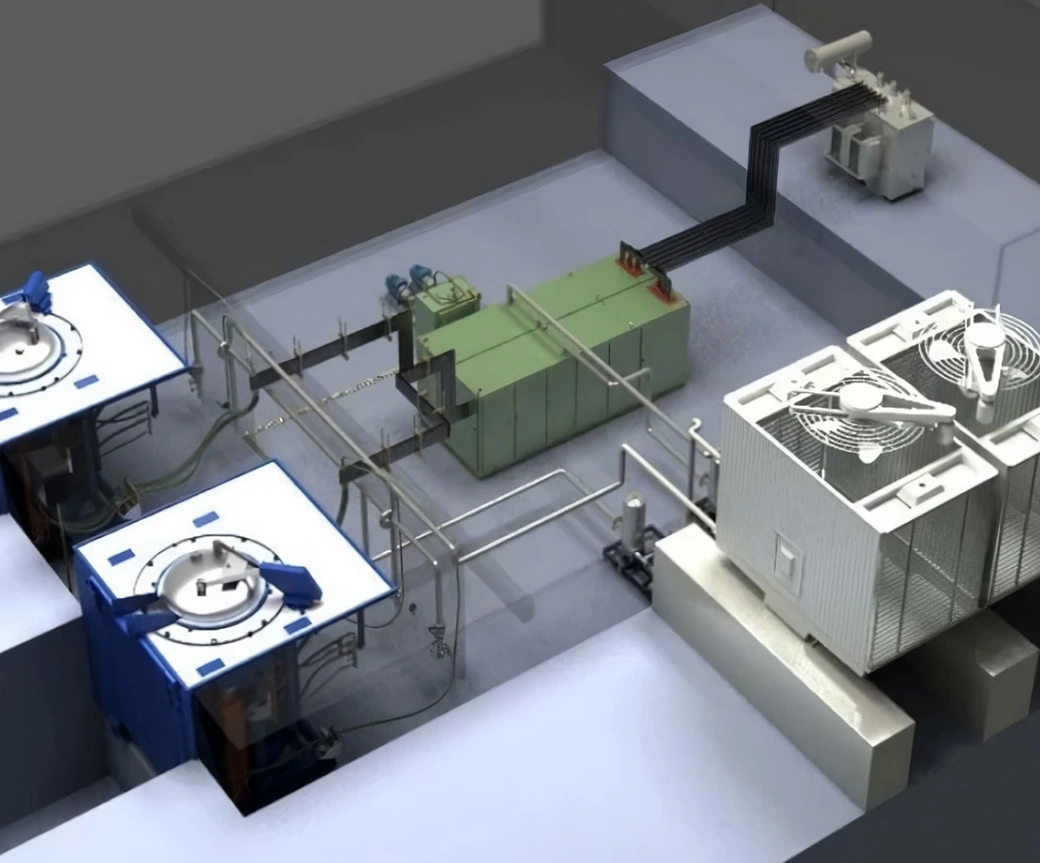

ONE ELECTRIC TWO FURNACE COPPER MELTING FURNACE

◎ 1000KG medium frequency furnace system is used for the production of copper and copper alloy. It is powered by a set of single frequency converter not less than 800KW.

◎ The power supply is composed of two coreless steel shell induction melting furnaces and auxiliary equipment required for normal operation of the system.

◎ One parallel resonant output power supply with two electric furnaces.

◎ The power cabinet and furnace body use their own independent closed-circuit circulating water system, which is completed by the user.

DESCRIPTION

The project covers the process, design Manufacturing, supply, installation guidance, commissioning and function realization, mainly including 1 set of 1000KVA transformer, 1 set of medium frequency power supply not less than 800KW, 2 sets of molten copper steel shell furnace body, 1 set of furnace leakage alarm device, 1 set of reactive power compensation capacitor bank, 2 crucible molds, 1 closed cooling tower.

The rectifier transformer is used to reduce the primary high voltage to a suitable medium frequency. The input voltage of the power supply adopts a special high impedance oil immersed self cooling type. The model of rectifier transformer is ZS series.

TECHNICAL PARAMETERS

|

Type |

ZS series 1 set |

|

Rated capacity |

≥ 1000 KVA |

|

Number of phases |

3 phases and 6 veins |

|

Rated frequency |

50Hz |

|

Rated voltage |

10 kV at high voltage side; Low voltage side (1) 0.66kv |

|

Voltage regulation mode |

No-load magnetic voltage regulation, 5th gear |

|

Tapping range |

10kV ± 2 × 2.5% |

|

Connection group |

dd0y11 |

|

Short circuit impedance |

6% |

|

Insulation level |

li75ac35 / AC5 |

TECHNICAL REQUIREMENTS

1) Cooling mode: oil immersed self cooling.

2) Voltage regulation mode: no-load voltage regulation

3) Transformer temperature rise: coil (resistance method) 65 ºC

Top oil layer (thermometer method) 55 ºC

Oil tank and mechanism surface 80 ºC

4) Shielding shall be added between high and low voltage windings, and the oil tank shell shall be reliably grounded through clamps.

5) The insulation grade of transformer insulation material is class A.

6) Short circuit impedance, no-load loss and load loss are based on the rated capacity of fundamental wave.

7) A magnetic separator plate or magnetic strip shall be installed between the low-voltage porcelain bushing and the box

8) Low voltage transformers are connected by copper bars.

9) The radiator of rectifier transformer adopts chip radiator.

10) The transformer is equipped with an oil sample valve, and there is an oil drainage device at the bottom of the transformer oil tank.

11) The sealing ring of transformer adopts acrylate rubber to ensure that the transformer works at the highest temperature and the lowest temperature

There is no oil leakage.

12) The transformer core is made of high-quality cold-rolled silicon steel sheet of WISCO, and bound with 45 ºC full inclined seam glass ribbon without holes

Structure. The coil adopts high-quality oxygen free copper electromagnetic wire. It can withstand short circuit, unexpected temperature rise, noise and vibration

Load iec551.

13) The transformer shall be filled with vacuum oil to completely remove the moisture in the insulating material.

14) The oil tank surface adopts phosphating and electrostatic spraying process after spray treatment.

15) Overload capacity: 125%, 2 hours; 200%, 10 seconds. When 110% of the rated voltage, it can be operated for a long time under no-load

that 's ok. At 105% of rated voltage, it can operate for a long time under rated current.

16) Noise level: noise ≤ 60dB