Low voltage high current up current generator

Low voltage high current up current generator is a special form of isolation step-down transformer, which is divided into single-phase and three-phase. The high current transformer is mainly single-phase. The single-phase model is tddg and the three-phase model is tsdg. The characteristics of this series of products are that the primary (input) voltage is civil or industrial voltage 220, 380, 440, 480, 660, 1140V, etc., the secondary (output) voltage is as low as a few V to tens of V, and the current varies from several times to tens of times of the input terminal. No matter in test, spot welding, welding, heating and current raising, this series of transformers need to step down from the power supply voltage to raise the current, so that the low-voltage current can reach thousands or more than 10000 amps. The input voltage is usually single-phase 220V, single-phase 380V or three-phase 380v-660-1140v. The secondary voltage varies due to the load current and resistance, usually 1.5V, 3V, 5V, 6V, 7V, 9V, 12V, 15V, 24V and 36V. The input and output voltage and current are carefully designed and manufactured according to the customer's application requirements.

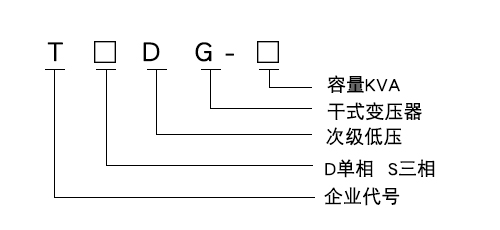

Model and its meaning

Technical parameter

Number of phases: single phase

Capacity: 500VA ~ 2000kVA

Input voltage: single phase / three phase: 220V 380V (can be customized as required)

Output voltage: 1.5v/3v/4v/5v/7v/8v/9v/12v/15v/18v/24v/36v (customizable)

Frequency: 50 / 60Hz, within 1000Hz as required

Efficiency: ≥ 95%

Insulation grade: F grade, H grade and HC grade are optional (conventional H grade) temperature resistance 180 °

Work efficiency: 95%

Waveform distortion: no additional waveform distortion

Insulation resistance: ≥ 50m Ω

Temperature rise: 60K

Electrical strength: power frequency sinusoidal voltage 3500v for 1 minute without breakdown and flashover

Overload capacity: double the rated current for 1 minute

Executive standard: the product complies with vde0550, iec439, jb5555 and gb226

Ambient temperature: - 20 ℃ ~ + 50 ℃

Humidity: ≤ 95% RH, no condensation

Altitude: < 1000M

Relative humidity: < 90%

Cooling mode: dry self cooling / air cooling / water cooling

Workplace: no corrosive gas and conductive dust

Note: the installation site is free of gas vapor, chemical deposition, dust, dirt, other explosive and corrosive gases and conductive dust that seriously affect transformer insulation

What parameters do custom transformers need to provide?

1. Rated power: output voltage × electric current;

2. Working frequency: generally 220V / 50Hz in China, which can be customized within 1000Hz

3. Output voltage: rated working voltage and no-load voltage

4. Output current: output rated working current or no-load current

5. Overall dimension: length, width and height of transformer

6. Special requirements: other special shall refer to temperature rise, efficiency, insulation grade, voltage regulation rate, wiring mode, etc.

7. Scenario usage: when designing special transformers, technical engineers need to understand the industry and working scenario in which the transformers are used, so as to design transformers that meet the user's needs

Product quality assurance and service guarantee of the company:

Before leaving the factory, each product is fully inspected in strict accordance with the national standard to ensure that the factory pass rate is 100%, and all products are guaranteed for one year( (except for special customer requirements)